Doors

West Central Manufacturing doors are of the highest quality construction and materials with no visible seams. They are constructed for extra heavy-duty applications.

West Central’s New and Improved Door Design is Designed to exceed all specifications.

Heavier 14ga Full Height Edge Reinforcement extends the Full Height of both the Hinge & Lock edges these are in addition to standard 7ga. Hinge reinforcements

Our Doors are a true Seamless Door; All doors are fully welded, ground and finished. Never tacked and filled with putty.

Other Standard Features

- 5” x 20” 12ga.

- Closer Reinforcement Steel Stiffened (unless dictated otherwise)

- Interior inverted top and bottom channels

- Exterior Flush Top Channel and bottom channels w/ weep holes

- Voids between ribs are filled with 4lb. Mineral Wool or Styrene

- Exterior doors 10 lb. mineral wool added under ribs.

- Thermal rated doors urethane insulation between & under ribs

This Door was designed to not only surpass our competition specs, our door was designed to provide the quality, longevity and life safety your customers desire

As always there is no up-charge for most custom hinge locations.

We're dedicated to finding new ways, and continuing in our current ways, of being as green a manufacturer as we can be. Learn more here!

We're dedicated to finding new ways, and continuing in our current ways, of being as green a manufacturer as we can be. Learn more here!Door Types:

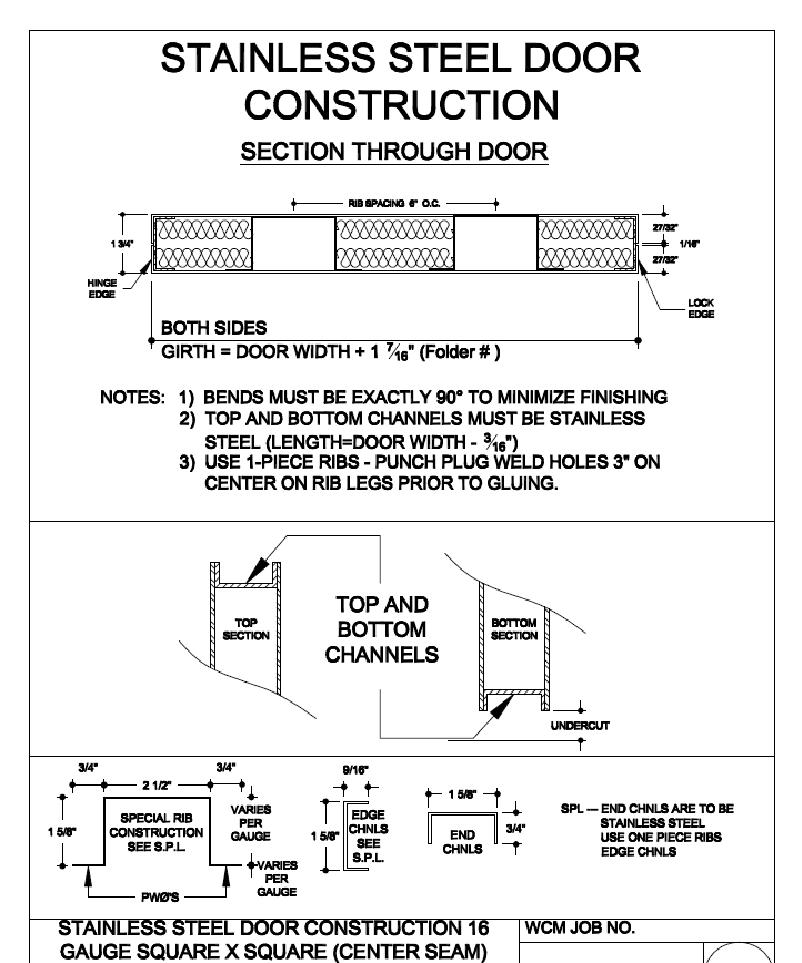

Stainless

Aesthetically pleasing and durable doors for demanding applications.

The most common stainless used in door construction is 304 with a #4 finish.

Stainless 316 with a #4 finish is available for high corrosive areas.

Available styles are Flush, Narrow lite and Half glass

Maximium size 44” x 120”

Standard core steel stiffened with Minerial wool between stiffeners.

Alternate cores are fill under ribs as well as in between with mineral wool, Polystyrene or Urethane. Urethane will offer the best R value.

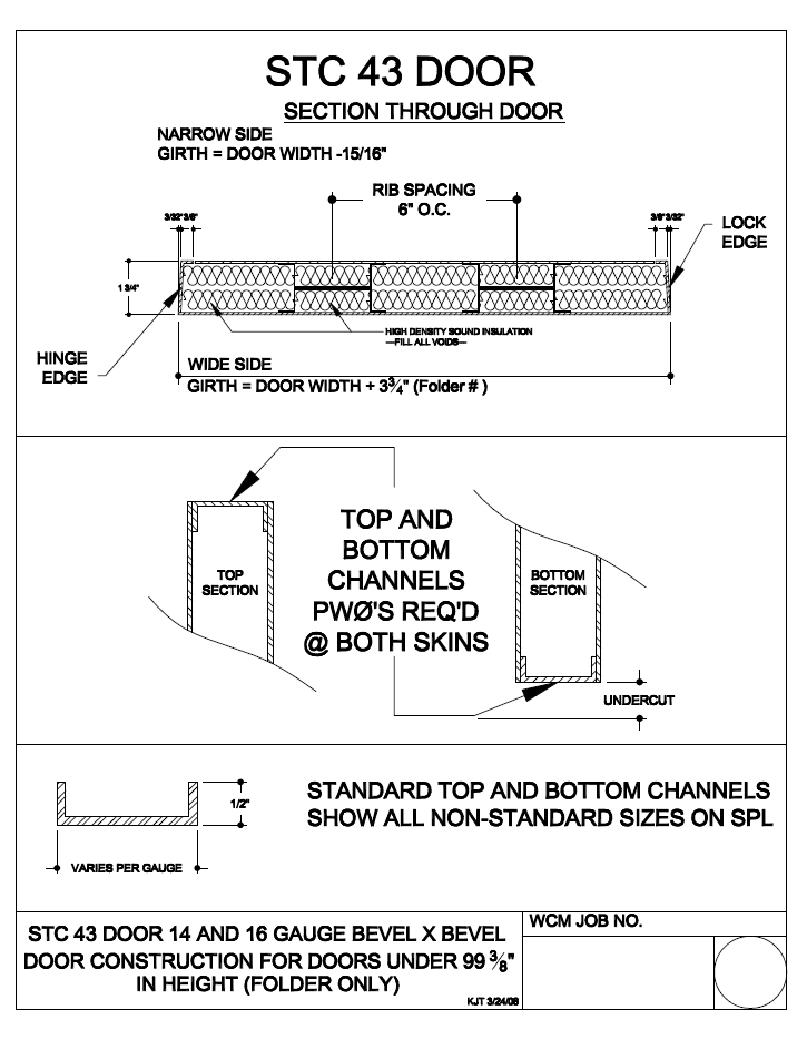

STC Doors

Acoustic doors provide outstanding sound transmission loss and provide increased privacy.

Door

-

12,14, or 16-Gauge

-

Vertically steel stiffened, seamless edge.

Maximum Sizes

Singles: Pairs:

-

4'-0" x 7'-0" or 8'-0" x 7'-0" or 7'-2" x 8'-0"

-

3'-6" x 8'-0"

Sold as package. Includes Doors, Frame, Sound Seals, Threshold and Astragal on pairs.

STC Ratings

-

STC 43: Single: Flush

-

STC 43: Single: Flush

-

UL Label 1 1/2 Hour

-

3'-0" x 7'-0" Max Size

-

-

STC 41: Single: Vision Lite

-

3"x 33" exposed glass or

-

10" diameter round

-

-

STC 38: Pair: Flush

|

SOUND TRANSMISSION CLASS (STC) |

||

|

STC VALUE |

RATING |

DESCRIPTION |

|

50-60 |

Excellent |

Loud sounds heard faintly or not at all |

|

40-50 |

Very Good |

Loud speech heard faintly but not understood |

|

35-40 |

Good |

Loud speech heard but hardly intelligible |

|

30-35 |

Fair |

Loud speech understood fairly well |

|

25-30 |

Poor |

Normal speech understood easily & distinctly |

|

20-25 |

Very Poor |

Loud speech audible |

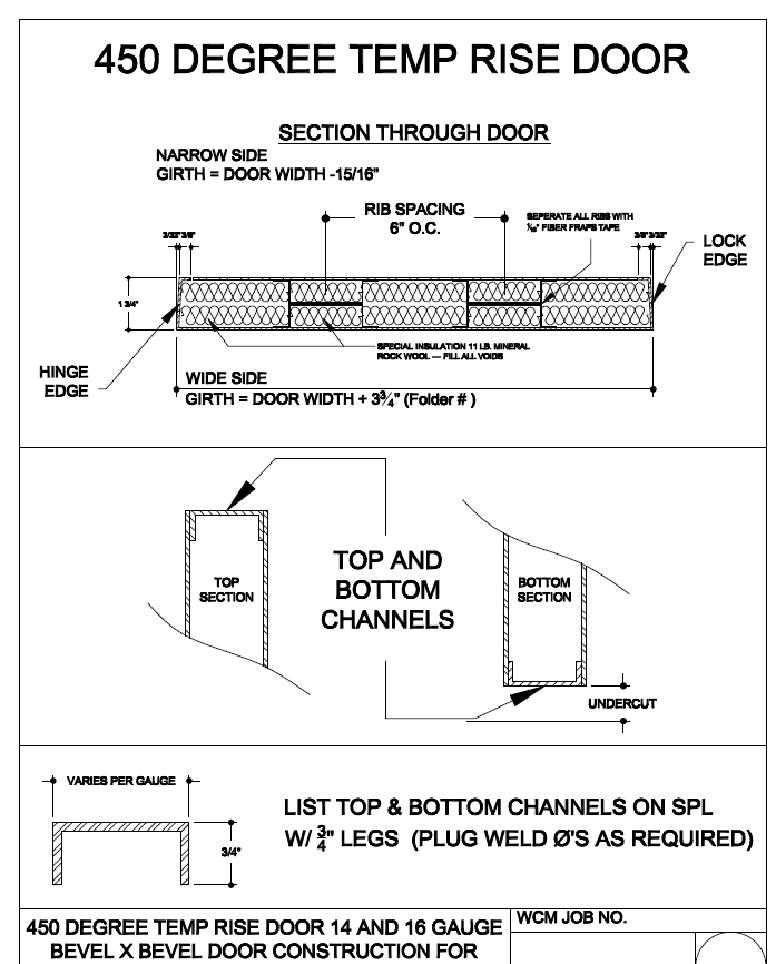

Temperature Doors

A temperature rise door is used when it is required to retard the transmission of heat from one area to another. It is a measurement of the rise in temperature above ambient temperature of the non-exposed side of the door during the first 30 minutes of the standard fire test. The lower the degrees, the better the rating. The currently accepted norm is a 250 degree rise over 30 minutes. A temperature rise rating is not required for a standard labeled fire door.

The 250 degree temperature rise designation is the most stringent rating since it requires the most limiting rise in temperature. A 250 degree temperature rise door meets the requirements of specifications calling for a 450 degree temperature rise rating.

Temperature rise doors are generally used in stairwells of high-rise buildings. The doors are used to limit the temperature rise through the door into the stairwell for a period of time, thus making it possible for people to exit the burning building by safely passing by the floor of the origin of the fire.

Material -16 or 14-gauge sheets of commercial grade A60 Galvannealed.

Core -Steel Stiffened

Reinforcements

Top and bottom of doors shall have continuous 16-gauge steel channels, spot welded to both sides of doors.

- Hinge reinforcements shall be 7-gauge steel, 12" long.

- Cylindrical lock reinforcement shall be 16-gauge.

- Closer and Panic hardware must be thru-bolted.

Edges of door shall be continuously seam welded, ground, and filled to ensure a smooth finish.

Hinge Backset - 1/4" standard. 3/16" or 1/8" available.

Finish - Doors shall be thoroughly cleaned after assembly and given a prime coat of rust inhibiting paint. The primer shall be air dried. Low gloss oil base trim paints (max gloss 25) are recommended as a finish paint.

Undercut - 3/4" standard. Other undercuts as specified.

Astragals - Flat 12-gauge astragals are provided with pairs of doors as needed and are shipped loose for field mounting.

Size Limitations

- Largest single door available: 4-0" x 8-0"

- Largest pair size available: 8-0" x 8-0"

Vision Light

Up to 100 square inches exposed.

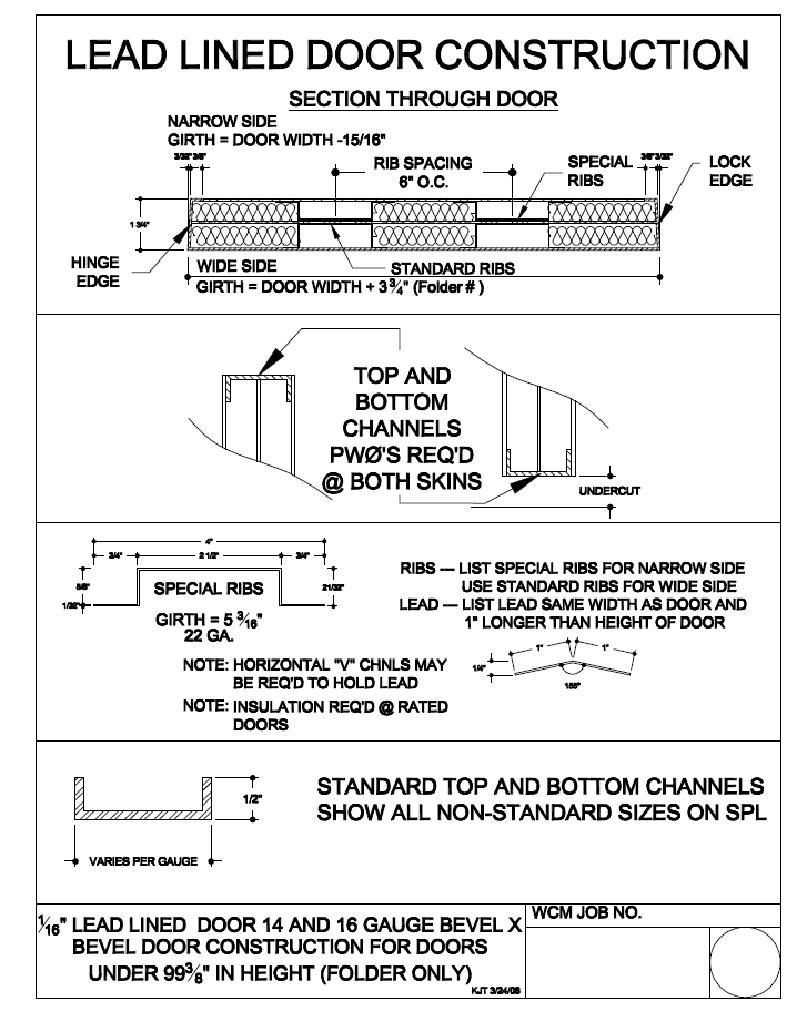

Lead Lined Doors

These doors are designed to withstand radiation. These products are usually associated with the health care industry and the use of X-Rays, CAT scans, and MRI's.

The weight and thickness of lead-lined doors is determined by the thickness of the lead required to withstand specific levels of radiation.

Most doors and door frames are made with 1/8" or 1/16" thick lead. Consequently they weigh 200-300 pounds. West Central Manufacturing’s lead-lined doors are 1 3/4" thick and have the appearance of conventional hollow metal doors.

These products can be fire rated up to three hours. Lead is in the center of the door.

- Door ribs: high hat style.

- UL 20-minute Label without hose stream available.

- 8'-0" x 8'-0" Max Pair

- 1/16" or 1/8" Lead

Where lead thickness exceeds 3/16", doors are built 2” thick with a maximium of 3/8 lead. These doors cannot be fire rated.

Lead Thicknesses 1/16” thick 4 lb per square ft. and 1/8” 8 lb. per square ft.

Multiple layers are available up to 3/8

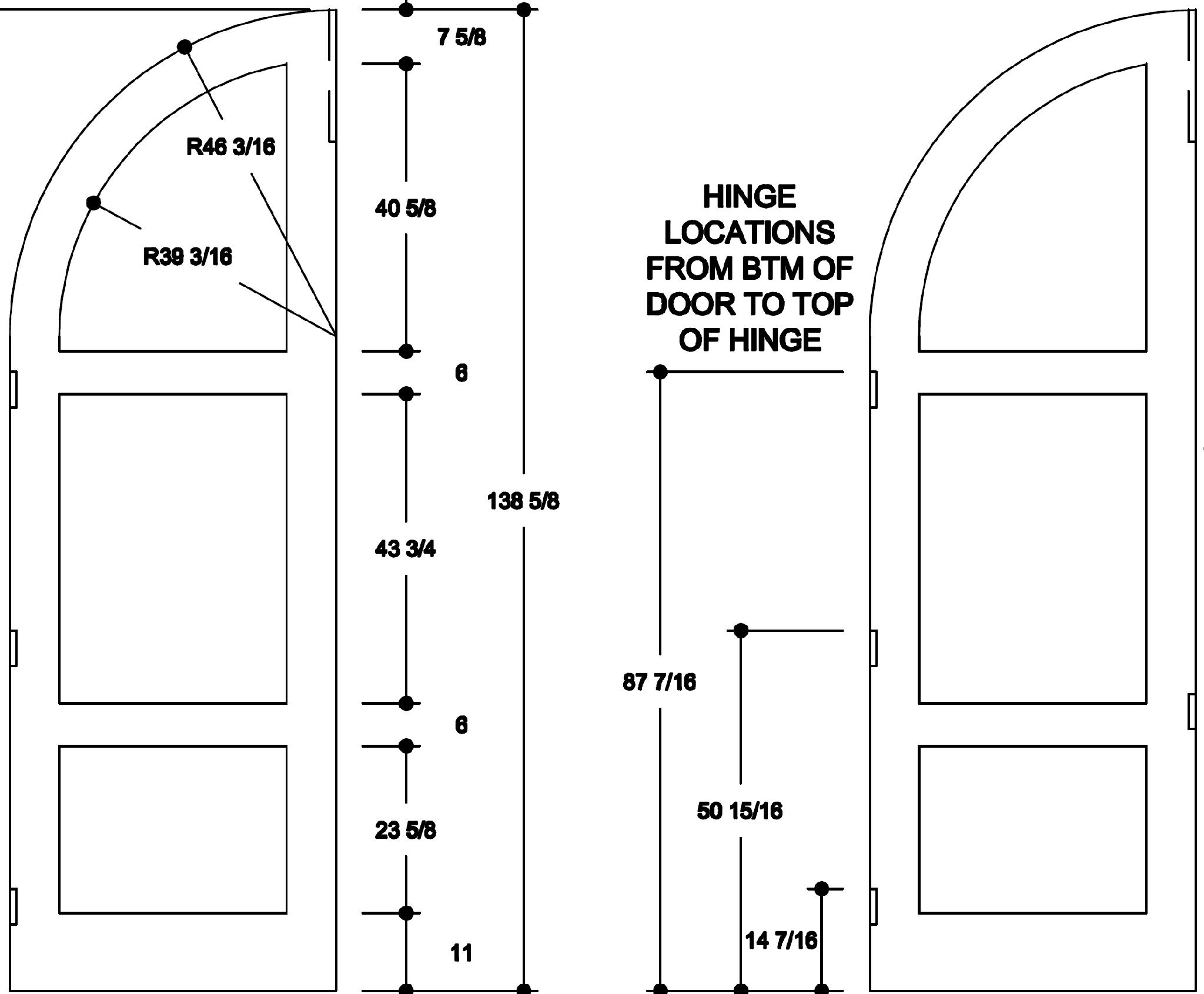

Radius Top Doors

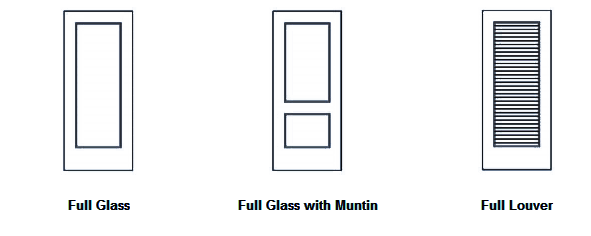

Radius Top Doors add an architectural flair and can be manufactures in many sizes and shapes. Flush, Narrow lite or Half glass or Large stile and rail as shown below.

All Radius doors are punched on computer operated Punch presses to guarantee a precise arch.

Dutch Doors

Dutch doors are doors that are split in two, top and bottom so that the top may swing independently of the bottom. The two leafs may be joined by a bolt (surface or flush). There is often a shelf between the two

Dutch doors can be made in any material or thickness. Therefore, they can be 1 3/4" thick, 1 3/8" thick or 2" thick. In additional they can be made in 16, 14, or 12 gauges. Dutch doors are available with vision lites or louvers. Doors can be UL Labeled.

3 Hour Label Dutch Door Details:

4'-0" x 7'-2" Maximum Single Door Opening.

Vertically Steel Stiffened - 16 or 14 Gage.

Top and bottom leafs must latch into strike jamb of frame.

Astragal provided between leafs.

Single or double shelf optional.

Dutch door with Radius Lite Kit.

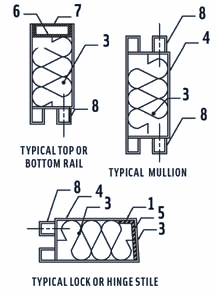

Stile & Rail Doors

West Central Mfg builds a high quality 14 ga. tubular Stile and Rail door. These doors are proof that you don't have to sacrifice design flexibility when selecting a heavy-duty stile and rail door. Our doors allow you to create the open and inviting full-vision entrance you want. While providing the functionality, security and long service life you require.

They're ideally suited for educational, institutional, commercial, or religious facility entrances subjected to high traffic.

West Central constructs a true, tube-style, stile and rail door from 14-Ga. minimum steel.

- Welded continuously full height-ground and finished

- Edges beveled 1/8' in 2

- Voids filled with 6 lb./cu. ft. mineral wool insulation

- Face sheets-as specified;14-gauge minimum

- 12-Gauge clips as required

- Inverted top and bottom channels (unless dictated otherwise)

- Flush filler channel at Ext.

- Applied glass stop on secure side of door (Glass stop detail may vary due to glass thickness)

Wicket Doors

Oversize Doors

West Central can build large industrial doors up to 20 ft tall and 2 ½ thick

The doors can be swinging mounted on hinges or sliding and hung from the top.

The doors are available with face sheets of 12, 14, or 16gauge cold roll or A60 Galvannealed.

Monorail cutouts and a wide assortment of hardware preparations are available, Pivots, mortised locks, and electrical are just a few.

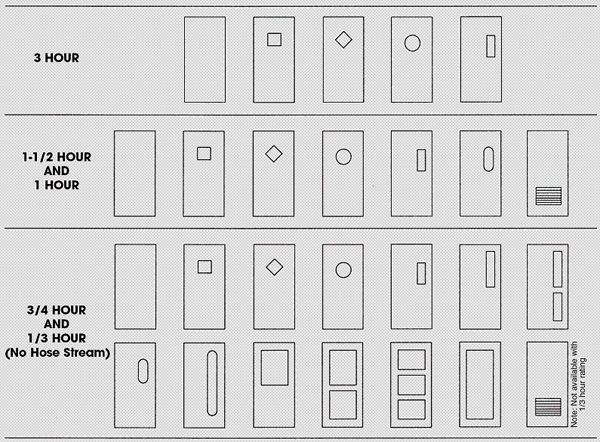

UL Labeled

West Central Manufacturing’s Fire rating abilities

|

LABEL |

DOOR DESIGNS |

MAXIMUM DOOR SIZES |

ALLOWABLE GLASS |

TRANSOM PANELS |

NOTES |

|

3 HR |

|

5' X 10' SINGLE |

FIRELITE ONLY |

NONE |

ASTRAGAL |

|

1-1/2 HR |

|

WITHOUT TRANSOM PANELS |

100 SQUARE INCHES MAXIMUM |

MAXIMUM |

ASTRAGAL |

|

1-1/2 HR |

|

WITHOUT TRANSOM PANELS |

MULTIPLES @ |

MAXIMUM |

ASTRAGAL |

|

3 HR |

|

10' X 12' |

FIRELITE ONLY |

NONE |

ASTRAGAL |

|

RATING & LABEL |

TYPE |

MAX DOOR SIZE |

SPECIAL NOTES |

|

|

3-Hour ("A") |

1 3/4" Doors |

5'-0" x 10'-0" (Single) |

|

|

|

1 1/2 Hour ("B") |

1 3/4" Doors |

5'-0" x 10'- 0" (Single) |

|

|

|

45 min. ("C") |

||||

|

20 Min. (Without Hose Stream) |

||||

|

3-Hour ("A") |

16 GAGE |

5'-0" x 10'-0" (Single) |

|

|

|

3-Hour ("A") |

Double Egress Pair |

8'-0" x 8'-0" |

|

|

|

Up to |

1 3/4" Thick |

5'x 12'-0" (Single) |

Auxiliary Fire latch required |

|

|

3-Hour ("A") |

Dutch Door - Single |

4'-0" x 7'-2" |

Top and bottom leafs must latch into strike jamb of frame. Astragal provided between leafs. Dutch door shelf is optional on push side. |

|

|

1 1/2-Hour ("B") |

|

3'-0" x 7'-0" |

Vertically steel stiffened. |

|

|

20 Min (Without Hose Stream) |

Lead Lined Door |

8'0" x 8'-0" (pair) |

|

|

|

1 1/2-Hour ("B") |

STC 43 Acoustical Assembly |

3'-0" x 7'-0" |

Flush Only. |

|

|

250 Degree 1 1/2-Hour ("B") |

Temperature Rise |

4'-0" x 8'-0" (Single) |

100 sq. in. exposed glazing max. |

|

CONSIDERATIONS FOR LABELED DOORS

- Must be prime painted or A60 galvannealed.

- Two Hinges for 60" jambs or less. One additional hinge for every additional 30" of height.

- Must have positive latching on opening (ie: panic, VR, strike).

VISION LITE AND GLAZING FOR LABELED DOORS

- Doors may be prepared for any UL Classified Glazing material classified for use with Hollow Metal Fire Doors

- Glazing needs to be listed and labeled.

- Temperature rise doors are allowed a maximum of 100 sq inches exposed.

- Light kits need to be listed and labeled for use in fire doors (such as NGP, Anemostat, etc) or as manufactured by Karpen Steel.

- Minimum 6" nominal rails to edge of cut-outs. Can go as low as 5 3/4" to accomodate stock VL kits.

- Minimum 6" nominal mid-rails (cut-out to cut-out).

- Chart Below shows maximum sizes based on available glazing options as of 2008. When other options become available, the doors can be UL labeled to accomodate the available glazing.

- "F" = glazing using Firelite brand of products

- "W" = glazing using wire glazing material

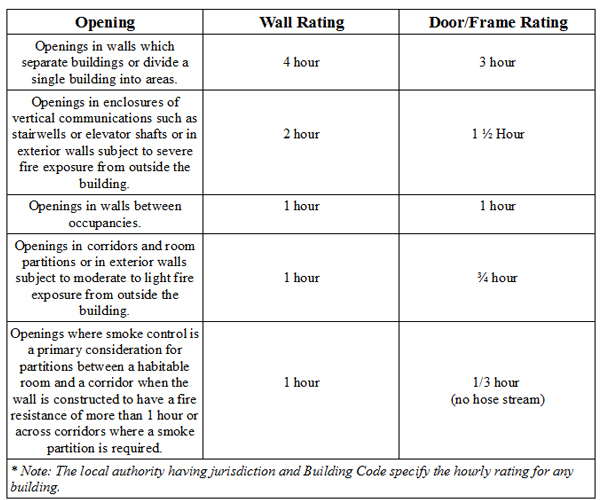

FIRE RATINGS

The industry sets the standards

Requirements apply to all fire doors

- Door and frame must be labeled.

- Self closing/latching in event of a fire

- Power operated doors will automatically cut power in event of a fire

- Auto closing doors may contain a hold open mechanism but must release in event of a fire

- Fire exit hardware must be equipped where 100+ load occupancy is present

|

DOOR |

Max Visible Area |

Max |

Max |

Notes |

|

3-Hr ("A") |

100 |

12" |

33" |

"F" |

|

1 1/2 Hr (90-min "B") or |

100 |

12" |

33" |

"W" |

|

1 1/2 Hr (90-min "B") or |

1296 |

36" |

54" |

"F" |

|

45-min (3/4 hr "C") or |

1296 |

36" |

54" |

"W" |

|

20-min |

3024 |

35" |

81" |

"F" |

|

20-min |

3024 |

35 3/4" |

83 1/2" |

"F" |